- Wednesday, April 23, 2025

Tata Sons, which owns JLR, selected Bridgwater in Somerset, southwest England, as the location for ambitious project, preferring it over a competing site in Spain.

By: Shubham Ghosh

INDIAN salt-to-software company Tata Group on Wednesday (19) revealed its plan to invest a staggering £4 billion (approximately Rs 42,500 crore) in the establishment of a flagship gigafactory, primarily focused on manufacturing batteries for Jaguar Land Rover and other carmakers.

The conglomerate, Tata Sons, which owns JLR, selected Bridgwater in Somerset, southwest England, as the location for the ambitious project, choosing it over a competing site in Spain.

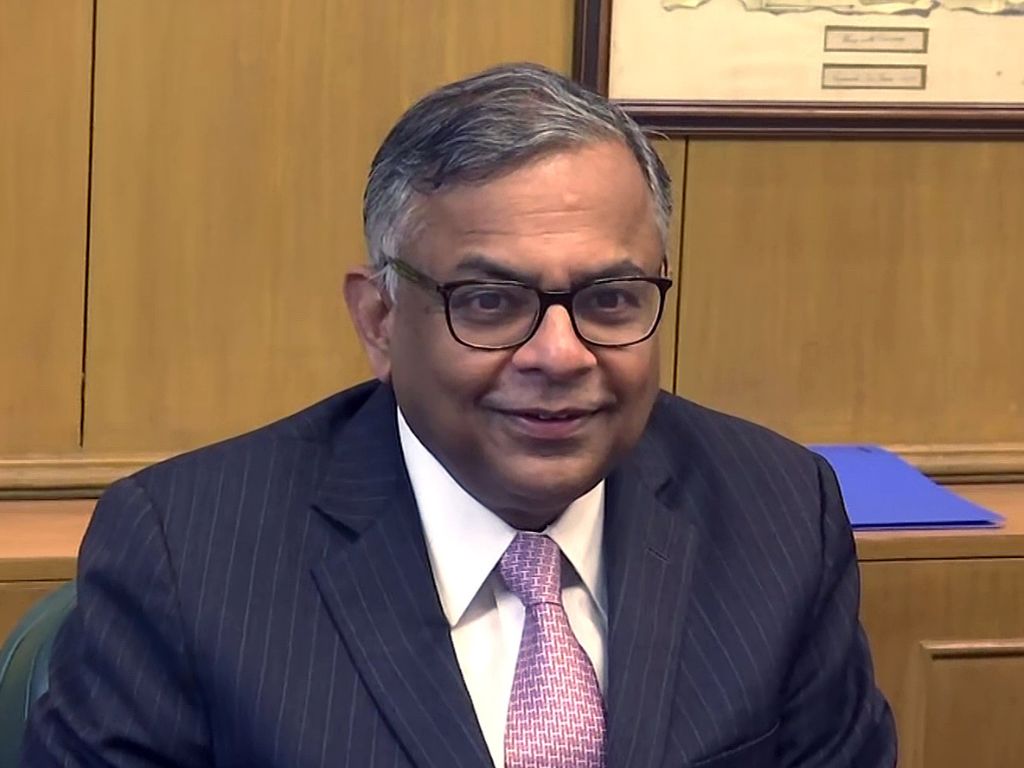

Our Chairman N. Chandrasekaran with the UK Prime Minister, @RishiSunak at The Jaguar Land Rover Gaydon Centre, in Britain after Tata group announced a £4 bn investment plan to establish a global battery cell gigafactory in the UK.

Read more: https://t.co/ppESwO9VmN #ThisIsTata pic.twitter.com/8sfvl2nS44

— Tata Group (@TataCompanies) July 19, 2023

Set to be one of Europe’s largest, the gigafactory will boast an impressive capacity of 40GWh, marking Tata’s first venture outside of India. The momentous plant has been hailed as the most significant investment in the UK automotive sector since Nissan’s arrival in the 1980s and is rumoured to have received substantial subsidies, although specifics were not disclosed by either the company or the UK government.

The primary focus of this factory will be to supply battery electric models for JLR, including iconic brands like Range Rover, Defender, Discovery and Jaguar.

Additionally, there is potential to provide batteries to other automobile manufacturers. Production is set to commence in 2026, with Tata reportedly seeking £500 million in state assistance from the UK government.

The requested support includes subsidies to account for the factory’s high-energy consumption, a one-off grant from the automotive transformation fund, and improvements to the site’s infrastructure.

The investment reflects Tata Group’s commitment to electric mobility and renewable energy storage solutions, establishing a robust green tech ecosystem on a grand scale in the UK. Batteries, which constitute more than half of an electric vehicle’s value, will be at the heart of this transformation.

With the current UK automotive landscape featuring only one operational battery plant near Nissan’s Sunderland factory and another in the planning phase in Northumberland, this gigafactory will be a game-changer. The European Union, by comparison, already boasts 35 operating, under-construction, or planned battery plants.

Tata Sons chairman Natarajan Chandrasekaran said, “The Tata Group is deeply committed to a sustainable future across all of our business. Today, I am delighted to announce the Tata Group will be setting up one of Europe’s largest battery cell manufacturing facilities in the UK.

“Our multi-billion pound investment will bring state-of-the-art technology to the country, helping to power the automotive sector’s transition to electric mobility, anchored by our own business, Jaguar Land Rover.

“With this strategic investment, the Tata Group further strengthens its commitment to the UK, alongside our many companies operating here across technology, consumer, hospitality, steel, chemicals, and automotive.”

Prime minister Rishi Sunak lauded the decision, considering it a tremendous vote of confidence in Britain, and anticipating the factory to play a pivotal role in strengthening the country’s position in the global electric vehicle transition.

He also said it will be one of the largest-ever investments in the UK automotive sector.

“It will not only create thousands of skilled jobs for Britons around the country, but it will also strengthen our lead in the global transition to electric vehicles, helping to grow our economy in clean industries of the future,” he said.

A statement from the UK government said the investment will create up to 4,000 new direct jobs, and thousands more in the wider supply chain.

The new gigafactory would provide almost half of the battery production needed by 2030 – turbocharging the UK’s switch to zero-emissions vehicles.

“This investment will be crucial to boosting the UK’s battery manufacturing capacity needed to support the electric vehicle industry in the long term. With an initial output of 40GWh it will also provide almost half of the battery production that the Faraday Institution estimates the UK will need by 2030,” it said.

(With PTI inputs)